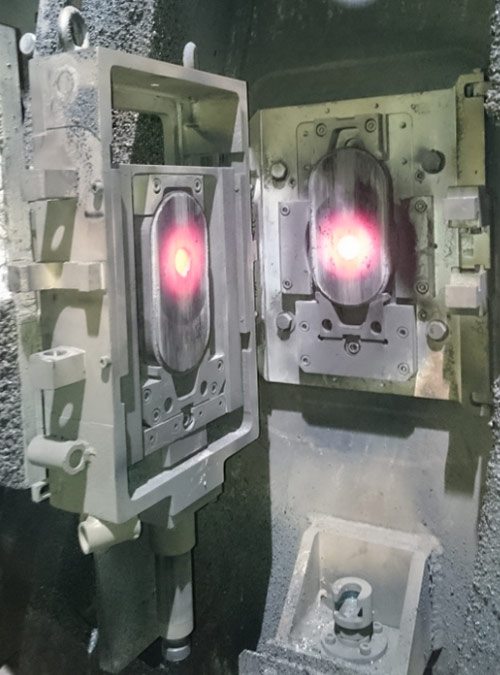

The FT100 and FT3 100GT – The Compact Sliding Gates for Small Steel Plants and Foundries

The latest development in the house of KNÖLLINGER is the sliding gate type FT100 which did its first operations with bravery. The assembling base on then bigger models FT200 and FT160 and therefore it owns the same advantages like robustness, long lifetime and simpleness.

By exchanging a few items, the mechanism can be primed for the use of 1QC or TS80 plates. Also similar kinds of plates are possible.

The weight is approx. 175kg and the maximum stroke is 105mm. Because of its compact design it is suitable for small steel plants or foundries.

The FT3 100GT

Of course, the 3-plate version, the FT3-100, is also available as a gas-guiding version, then with the supplement “GT”. This mechanism reliably minimizes, as all types of GT series, the re-oxidation inside the sliding gate, as well as in the area around the collector nozzle and the funnel. As a result, its users were able to significantly reduce their amount of scrap and improve their high-quality grades.

Like all GT-Types, the middle plate is guided in a hinged cassette. The 3-Plate Sliding Gate of the smallest series is particularly suitable for foundries and ingot casting plants with small ladles. So far, the FT3 100GT is operated with TS80 plates.

Galerie

2-Plate Mechanism FT100

3-Plate Mechanism FT3 100GT