GAS-TIGHT 3-PLATE LADLE SLIDING GATE VALVE (NOVELTY)

Standard version

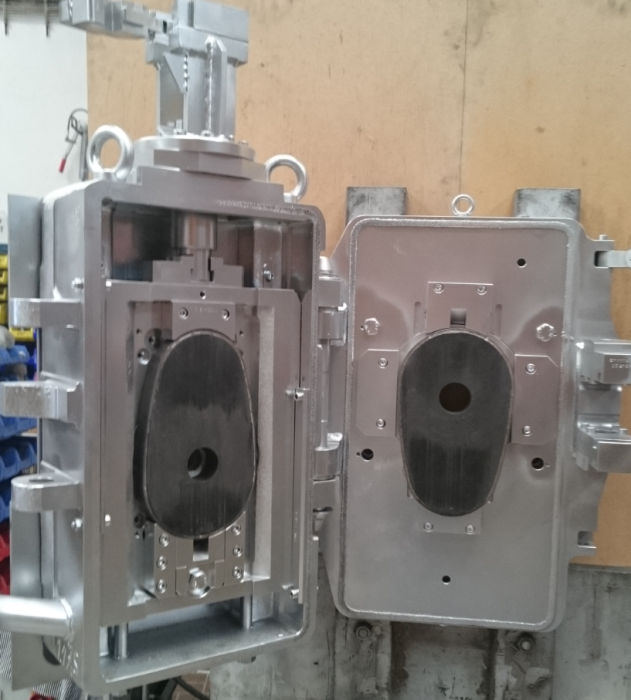

Clean steel with the Ladle Sliding Gate Valve Model FT3 GT

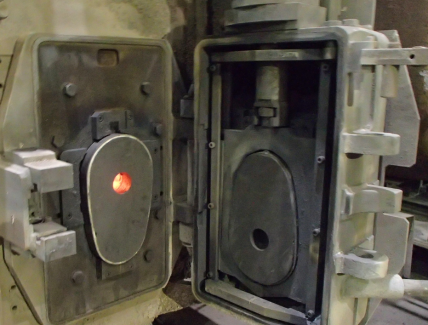

The FT3 GT is designed for customers with high demands for the quality of steel. The 3 plate sliding gate system forms a closed housing with high-temperature- resistant seals, into which inert gas can be injected at appropriate points. This shields the system against air ingress.

The gas passes through the ladle sliding gate valve, around the collector nozzle into the funnel or to the shroud. So a combination of stream and slide gate shielding is realized.

The FT3 GT is particularly user-friendly thanks to its patented opening method.

The middle plate is placed in a cassette, which can be easily swivelled open and thus allows free access to the bottom plate.

After a few modifications, the slide gate can be operated with different plate variants.

Previous versions

| TYPE | ø (mm) |

|---|---|

| FT 3 160GT | max. 65 |

| FT 3 200GT | max. 100 |

| FT 3 100GT | Plattenvarianten- abhängig |

FT3GT with End-Hinge

Also available as an end hinge mechanism (not implemented yet)

Ladle Slide Gate with End Hinge

The gas-carrying head hinge slide gate offers all the advantages that our gas-carrying 3-plate slide gates with standard hinge also offers. As with our 3-plate types with standard hinge, the patented opening method is particularly ergonomic, since the middle plate is paced in a swivelling cassette, which makes working on the hot slide gate as pleasant and quick as possible. By installing the long-life sealing cord, the robust, ergonomic 3-plate slide gate becomes a gas-carrying system that meets the highest demands on steel quality.

| TYPE | ø (mm) |

|---|---|

| FTK -3 160GT | max. 65 |

| FT K-2 GT | max. 100 |

The FTK2 GT is not yet in use, but can also be implemented on request.

NOVELTY: FT2 GT- Gas-Carrying Two-Plate Slide Gate for Continuous Casting

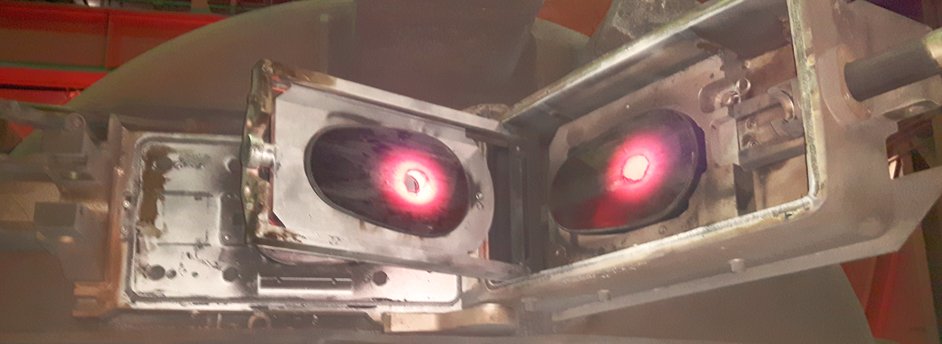

Like all slide gates in the GT series, the FT2 GT was developed for customers with high demands on steel quality. The two-plate ladle slide gate has a closed housing which is sealed with high temperature resistant seals. This enables the application of a barrier pressure by means of inert gas and the shielding from the outer atmosphere.

The gas is directed through the slide gate past the collector nozzle right onto the ladle shroud. In this way, a combination of ladle shroud fumigation and slide gate shielding is realized.

Also the FT2 GT is very user-friendly. The slide can be moved with different plate variants, identical to the FT universal ladle slide.

| TYPE | ø (mm) |

|---|---|

| FT 2 160GT | max. 65 |

| FT 2 200GT | max. 100 |

News

Gas-tight slide gate valve reduces reoxidation during steel casting

Find out more about this subject and download the publication here (PDF file). Article “Development of a gas-tight slide gate …” (529,6 KiB) Galerie