Two-plate slide gate valves

FT2GT for the CLEAN STEEL field

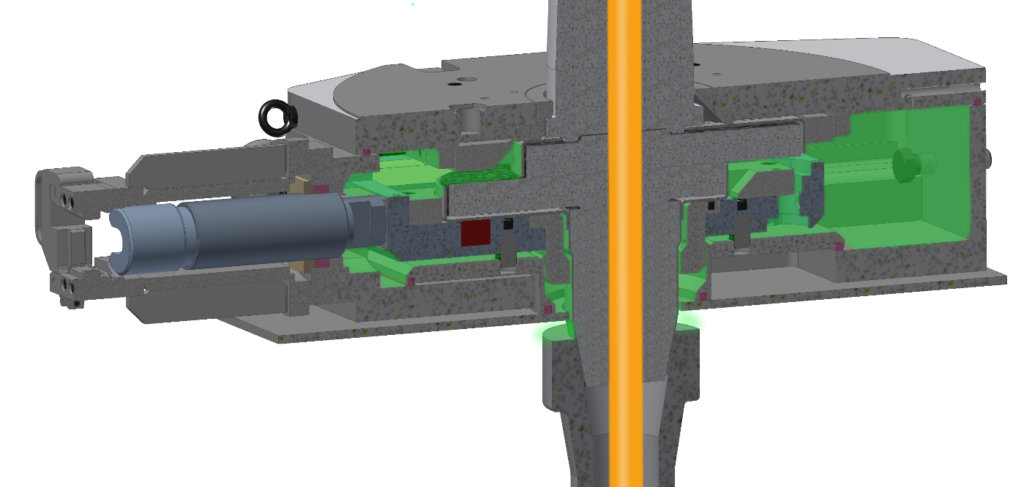

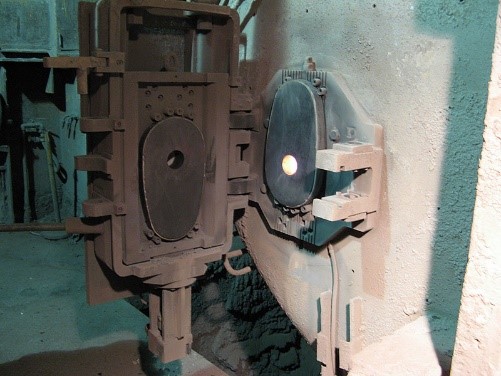

Gas-conducting two-plate slide gate type FT2GT

Like all slide gate valves in the GT series, the FT2 GT was developed for customers with high demands on steel quality and safety. The two-plate ladle slide gates have a closed housing, which is sealed with high-temperature resistant gaskets. This enables the application of a barrier pressure by means of inert gas and shielding from the external atmosphere.

The gas is directed through the slide gate past the collector nozzle onto the ladle shroud. In this way, a combination of ladle shroud gassing and slide gate shielding is realized.

The solid design also offers a considerable increase in safety. With slide gates of the GT design, steel leaks inside the valve can freeze, as the sealed design prevents hot steel from continuously flowing through the leak and the solid cast steel housing can extract enough energy from the medium to freeze. Particularly in continuous casting, our slide gate valves can therefore be used to install an additional safety device before the emergency run, which can save or protect the system, the contents of the ladle and, above all, the staff in the event of an emergency.

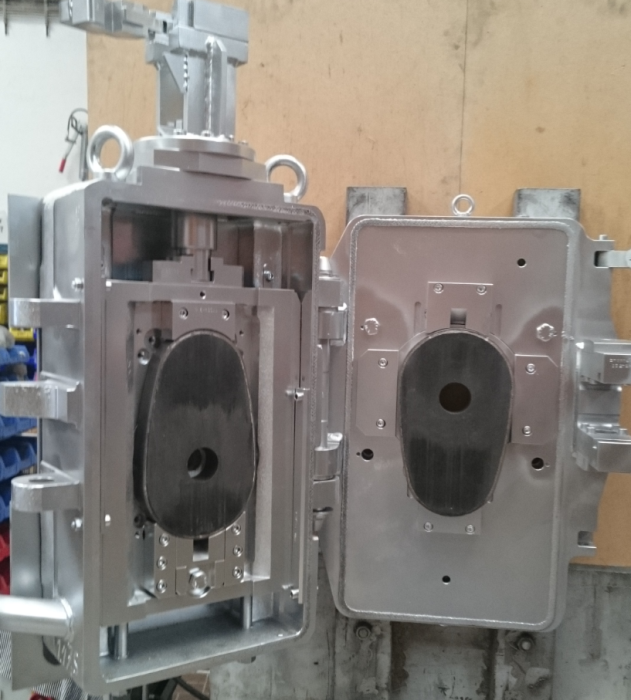

As always, the FT2 GT has been designed with user-friendliness in mind. In addition, the slide gate, like the FT universal ladle slide gate, can be operated with different plate variants.

The advantages of our two-plate ladle slide gate valve type FT2 GT at a glance:

- Competitive advantage by avoiding re-oxidation in the slide gate system (GT version only)

- The closed, solid design and the use of a moving sealing plate allow steel leaks to freeze inside the slide gate, thus protecting staff and equipment. (GT version only)

- The only ladle slide gate in the world that can be operated with different plate variants, e.g. type FT, LS, CS, FLO-CON etc.. This gives our customers independence and the ability to react quickly to changing market conditions.

- Quick and easy handling. The slide gate is closed or clamped by means of a lightweight hydraulic cylinder and secured by a locking pin. This enables extremely fast set-up times while leaving as little room for error as possible.

- The slide gate has indicator pins visible from the outside, which can be used to detect installation errors in the plates or the inner nozzle at the ladle preparation area from the outside.

| TYP | max: Hub / Stroke (mm) |

|---|---|

| FT 2 100GT | max. 100 |

| FT 2 160GT | max. 160 |

| FT 2 200GT | max. 200 |

Our own FT formats have the following maximum casting diameters, although these may vary in individual cases.

| TYP | ø (mm) |

|---|---|

| FT 160 | max. 65 |

| FT 200 | max. 100 |

FT-Universal-Slide Gate

As our ladle slides can be operated with a wide range of plate formats, we only indicate the maximum possible stroke of the slide gate below. The maximum casting diameter depends on the plate format used:

| SCHIEBERTYP / SLIDE GATE TYPE | max: Hub / Stroke (mm) |

|---|---|

| FT 200 | max. 200 |

| FT 100 | max. 100 |

| FT 160 | max. 160 |

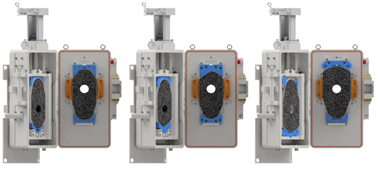

The FT100 type is suitable for smaller plates such as 1QC, TS80 or similar sizes. Here you can see an FT100 with 1QC plates which in this case have a casting diameter of 32mm. In this example, the slide gate is operated via a transfer linkage with automatic clutch. The ideal actuation is determined in cooperation with the customer:

The FT160 type is suitable for medium-sized plates such as our own FT160 format with a maximum casting diameter of 65mm. In the picture you can see installed plates of the LS70, this slide gate was converted by us so that it creates 170mm stroke and thus also larger casting diameters can be driven.

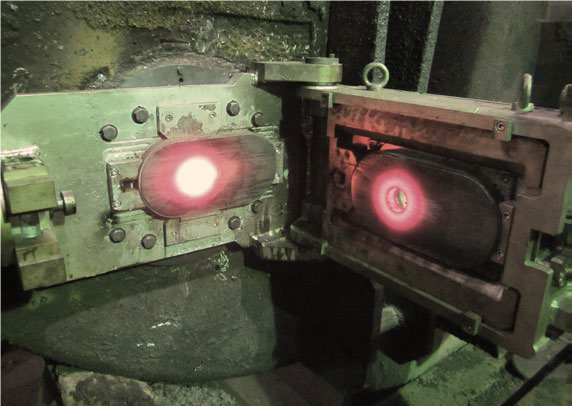

The FT200 type is suitable for larger plates such as our own FT200 format with a maximum casting diameter of 100 mm. These are also used in the picture. Symmetrical plate geometries such as the FLO-CON 6300 geometry or plates such as LS90 or CS80 from our competitors can also be used. Of course, all similar panel formats can also be used here. The adjacent picture also shows the cable for early slag detection from AMEPA, with which our slide gate systems can generally be equipped.

Our slide gates are also available as an end hinge version (FTK) in the event that the drive axle is arranged horizontally at the ladle preparation area.

The advantages of our UNIVERSAL ladle slide gate type FT at a glance:

- Quick and easy handling. The slide gate is clamped by means of a lightweight hydraulic cylinder and secured by a locking pin. This enables extremely fast set-up times while leaving as little room for error as possible.

- The slide gate valve can be operated with different plate variants, e.g. type FT, LS, CS, FLO-CON etc. This gives our customers independence and the ability to react quickly to changing market conditions.

- All our FT slide gates have indicator pins that are visible from the outside. These can be used to detect installation errors in the plates or the inner nozzle at the ladle preparation area at closed mechanism.

- Central, stationary contact pressure through special, durable, thermodynamic spring elements which not required cooling by expensive compressed air.

- Our ladle slides are available in all swivel directions so that we can install them on every ladle in the vast majority of cases.

Reading Material

Gas-tight slide gate valve reduces reoxidation during steel casting

Find out more about this subject and download the publication here (PDF file). Article “Development of a gas-tight slide gate …” (529,6 KiB) Galerie