FT3GT Three Plate Slide Gates

Gas carrying System

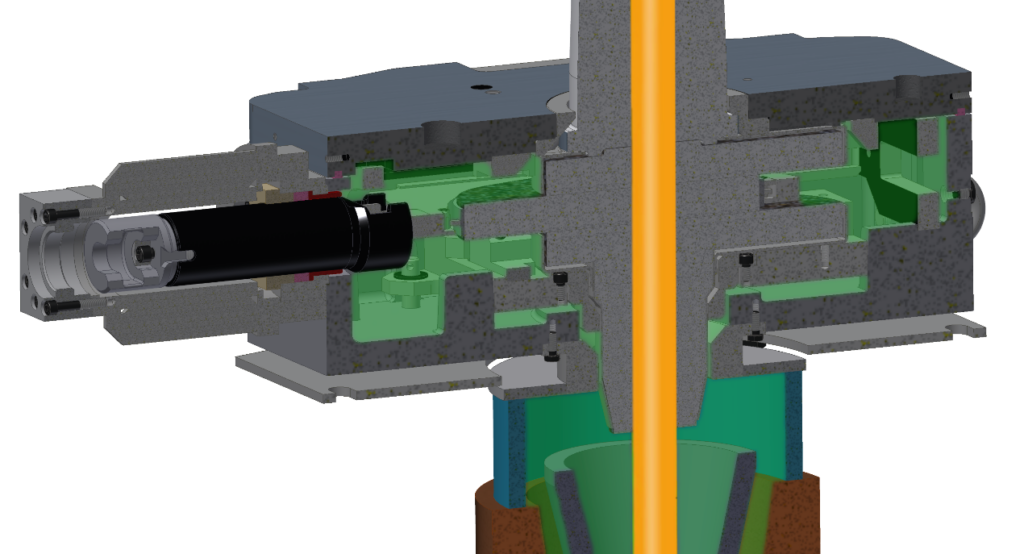

Gas-Carrying three-plate slide gate type FT3GT

Three-plate gate valves are ideal for ingot casting, as only the middle plate regulates and the bottom plate remains fixed. This means that the position of the casting stream does not change during casting and positioning above the funnel and shielding the pouring stream from oxygen is easier to achieve, resulting in a higher purity of the steel.

We developed our three-plate gate valves in the GT series with the aim of further improving the degree of purity of the steel and thus filling the gap in a ladle gate valve specifically for the CLEAN STEEL sector. This was achieved with a solid housing, which was fitted with suitable seals at the tactical points. Instead of just flushing the area around the spout with inert gas, the inside of the slide gate is flushed, with the gas then escaping around the bottom plate nozzle and flooding the funnel directly, thus protecting the pouring stream from oxygen and the atmosphere.

Our GT slide gates are also clamped and locked with a single locking bolt and a separate hydraulic cylinder. The patented bearing of the cassette, which holds the centre plate, also contributes to easy handling.

The construction of our three-plate slide gate valves is the same stable, solid and closed design as our two-plate gate valves. This means that when our customers purchase a ladle slide gate valve from the sealed GT series, they not only acquire a tool for casting clean steel, but also a safety-relevant device that prevents damage to staff and equipment in the event of steel leaks. A steel leak can always occur, as the assessment of the plates is carried out by people. If it occurs, there is a high probability that the liquid steel will simply freeze inside the gate valve after it has filled up.

If the actuating cylinder is in the direction of the push axis of the panels, a so-called standard hinge is used. We are happy to check individually and without obligation whether our customers require a right- or left-swinging ladle slide gate.

Our three-plate slide gates are usually equipped with our own, patent-free FT refractory format, as it is not so easy to convert to other panel formats due to the central frame with the corresponding shape. It is possible, but must be checked in detail.

Our three-plate slide valves are mostly equipped with our own, patent-free FT plate format because the central frame with its corresponding shape does not easily allow for conversion to other plate formats. It is possible, but must be examined in detail.

Our own formats have the following maximum casting diameters, although these may vary in individual cases.

| TYP | ø (mm) |

|---|---|

| FT 160 | max. 65 |

| FT 200 | max. 100 |

As our three-plate ladle slide gates are not as flexible as our two-plate slide gates, but can still be used with different plate formats, we also only specify the maximum possible stroke of the slide gate below. The maximum casting diameter then depends on the plate format used. However, as this is usually the patent-free FT plate format, the specifications are the same as those given above. Don’t let yourself get confused. We will work with you to find the ideal solution for your specific case!

| TYP | max: Hub / Stroke (mm) |

|---|---|

| FT3-200GT | max. 200 |

| FT3-100GT* | max. 114 |

| FT3-160GT | max. 160 |

* The FT3-100GT is equipped ex works with the TS80 plate format.

The advantages of our three-plate ladle slide gate type FT3GT summarized once again:

-

Competitive advantage due to CLEAN STEEL

-

The closed, solid design allows steel leaks to freeze inside the slide gate, thus protecting staff and equipment.

-

Quick and easy handling. The slide gate valve is clamped by means of a lightweight hydraulic cylinder and secured by a locking pin. This enables extremely fast set-up times and at the same time leaves as little room as possible for errors.

-

Indicator pins visible from the outside can be installed if required. These can be used to detect installation errors in the plates or the inner nozzle at the ladle preparation area at a closed housing.

-

Central, stationary contact pressure through special, durable thermodynamic spring elements that do not require expensive cooling with compressed air.

Our ladle slide gates are available in all swivel directions so that we can install them on every ladle in the vast majority of cases.

Reading Material

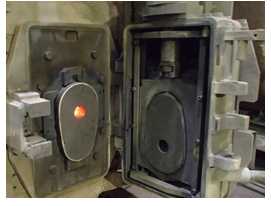

Gas-tight slide gate valve reduces reoxidation during steel casting

Find out more about this subject and download the publication here (PDF file). Article “Development of a gas-tight slide gate …” (529,6 KiB) Galerie